With our core competency as a trading and service provider, we are specialized in the construction of high quality injection moulds inclouding a full service and distribution support. International tool manufacturing provides a lot of procurement benefits, such as high quality, an attractive price-level and impressive short project run times. We precisely coordinate the entire process and closely communicate between customers and tool manufacturers in Far East. Beginning with the development, we coordinate and accompany the manufacturing process and monitor the projects right through to the mass-production stage.

With our german manufacturing facility we provide most possible flexibility in case of any tool-modification, repairs and last not least the manufacturing of new tools.

We stand for excellent competence, reliability and high quality. Decades of profound practical experience, a comprehensive service - logistic, an absolutely attractive and convincing price-benefit ratio, combined with a qualified customer service are our characteristic qualities.

The products of our service portfolio are found worldwide in automotive-, entertainment-, packaging-industry, medical technology and many other fields.

We emphasize maximum quality, security, long-lasting reproducibility and uniformity.

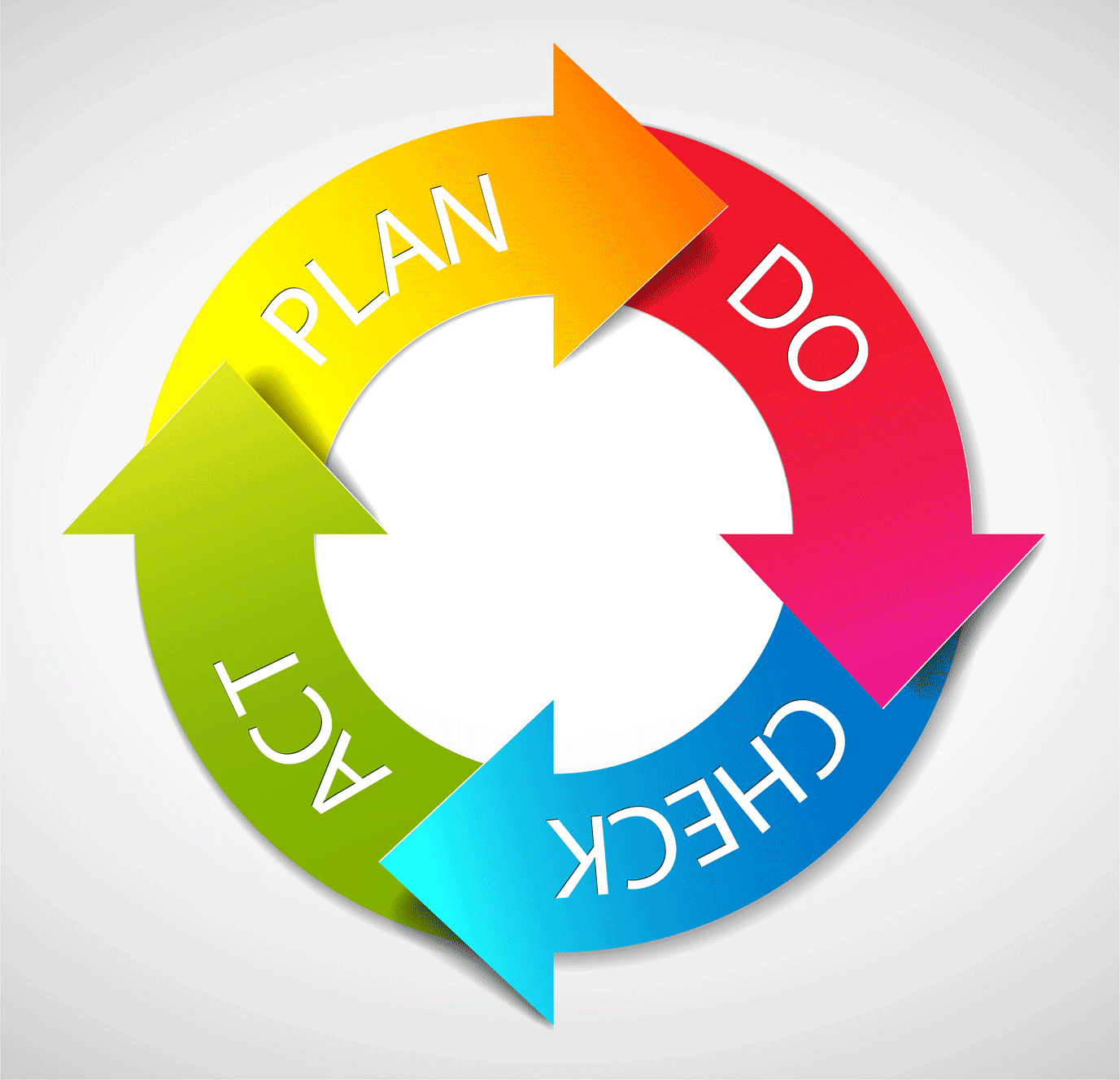

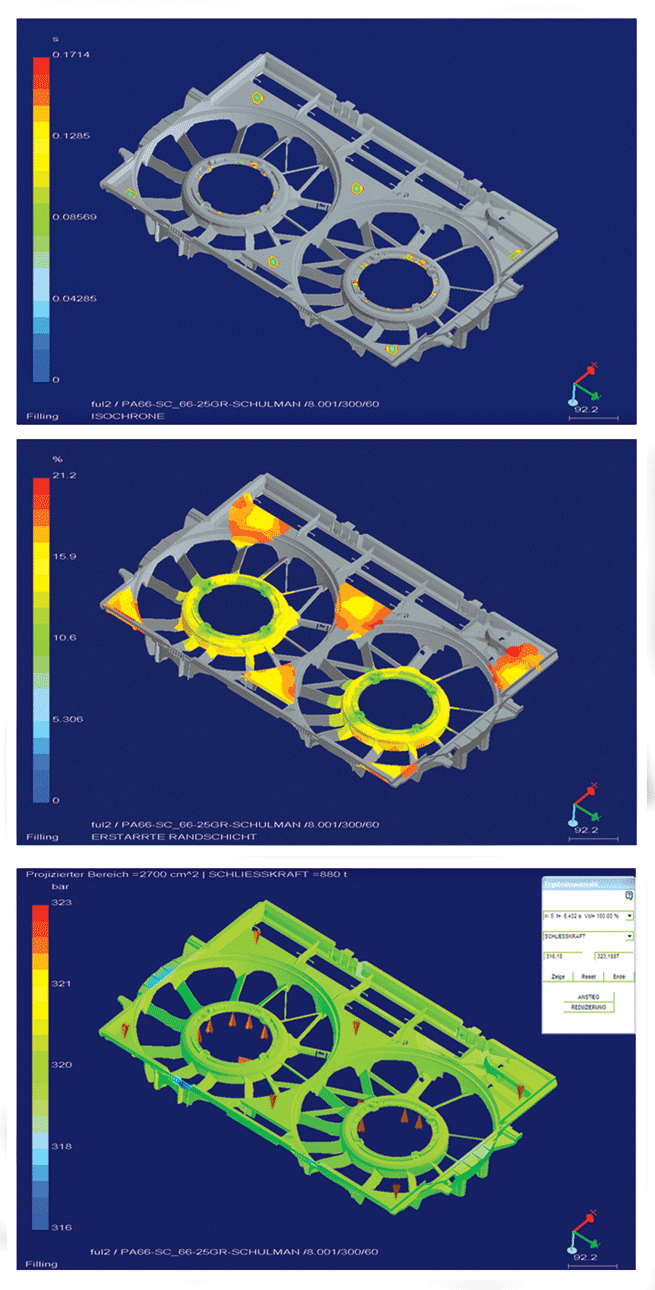

Before we start with the mould construction itself, we conduct a Mouldflow upfront, a simulation to get the ability to modify and optimize the design process and the entire product development cycle. During the construction phase each step is carefully controlled and supervised. After completion of the project, we provide all documents and data in DXF, Step or Parasolid to our customers.

Each construction and production process is completely and constantly accompanied by us. If not build on our own in Germany, our german leaded on-site management in Far East guarantees a close and optimal coordination of every step.

As the lightest of all metal materials, magnesium and it alloys offer a tremendous potential for applications in the field of modern light-weight engineering. Often the use of these materials makes sense and will pay off in the long run. Years of experience in this sector are our strengths.

For pre-manufacture-testing of parts, minimized development costs and a significantly reduced manufacturing time are major advantages of prototyping moulds. Build on the results, final decisions could be made for the tool-construction for the line-production.

From development via construction, simulation, optimization up to the final release of the mould, we accompany the whole project.

With a continous communication and the documentation of all steps, a maximum of transparency is provided.

Each phase is constantly accompanied by us. A personal and individual supervision and verification of trials under manufacturing conditions are part of every construction project.

Our aim and ambition are maximum quality, long-lasting reproducibility and perfect uniformity.

The first is located in Shenzhen, in direct neighbourhood to Hong Kong. Second is found in Hangzhou, about 200km away from Shanghai.

Both locations are known as strongholds of the toolmaker industry.

With our experienced team, we stand by your side during the realisation of projects.

In order to continously provide outstanding quality, all our machinery is equipped with state-of-the-art technology and operated by highly qualified staff to build excellent moulds.

We are prepaired for any kind of mould, tool system and surface. As a competent and reliable partner we fully support you in all areas of tool manufacturing.

For now we are not seeking for an employee!

Please send us your application documents by e-mail or use our online application form.

phone: + 49 4503 8986 484

fax: + 49 4503 8986 485

e-mail: info@gefa-automotive.de

Managing director: André Tuntsch

responsible for the content in accordance with §5 and §55 RStV:

gefa - German Engineering for Automotive GmbH

Zur Teerhofsinsel 10a, Tor 9

23554 Lübeck

phone: +49 451 88 0607 - 0

fax: +49 451 88 0607 - 20

internet: www.gefa-automotive.de

e-mail: info@gefa-automotive.de

managing director: André Tuntsch

commercial Register: Amtsgericht Lübeck

registration number: HRB 10630 HL

VAT: DE 275342926

powered by ERP-Software easyWinArt

According to §§8 to 10 of TMG, we are not obligated to monitor third party information provided or stored on our Web site. However, we shall promptly remove any content upon becoming aware that it violates the law. Our liability in such an instance shall commence at the time we become aware of the respective violation.

Liability for Links

Our site contains links to third-party Web sites. We have no influence whatsoever on the information on these Web sites and accept no guaranty for its correctness. The content of such third-party sites is the responsibility of the respective owners/providers.

At the time third-party Web sites were linked to ours, we found NO GROUNDS WHATSOEVER of any likely contravention of the law. We shall promptly delete a link upon becoming aware that it violates the law.

Copyrights

The content and works provided on these Web pages are governed by the copyright laws of Germany. Duplication, processing, distribution, or any form of commercialization of such material beyond the scope of the copyright law shall require the prior written consent of its respective author or creator.

Data Protection

Please be aware that there are inherent security risks in transmitting data, such as e-mails, via the Internet, because it is impossible to safeguard completely against unauthorized access by third parties. Nevertheless, we shall safeguard your data, subject to this limitation. In particular, personal information will be transmitted via the Internet only if it does not infringe upon third-party rights, unless the respective party has given its prior consent in view of such security risks. Accordingly, as the Web site provider, we shall not be held liable for any damages incurred as a consequence of such security risks or for any related acts of omission on our part.

We oppose the use of any available contact information by a third party for sending unsolicited advertisements. As the Web site provider, we reserve the express right to take legal action against unsolicited mailing or e-mailing of spam and other similar advertising materials.

last update, Thursday, 23. August 2011